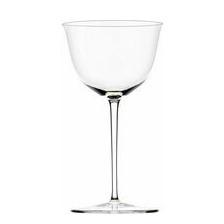

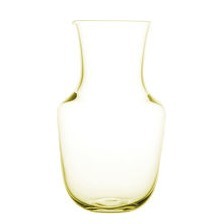

Lobmeyr

Schon der Urgroßvater des aktuellen Geschäftsführers hat sich den Künstlern der Wiener Werkstätte zugewandt. Bis heute kommen die Gestalter aus unterschiedlichen Bereichen, sie sind Maler, Architekten oder Designer. So reicht auch ihr Repertoire vom klassischen Zylinderbecher von Adolf Loos hin zum Martini- und Champagnerglas von Oswald Haerdtl aus 1925 und Superklassiker-Glas aus 1856 vom Ludwig Lobmeyr.

Lobmeyr bricht die Selbstverständlichkeit des allgegenwärtigen Werkstoffs auf und trägt dessen Eleganz und Feinheit zurück in den Alltag.

Der Gründer von FORMOST Matthias Kanter erzählt über das feine mundgeblasene Musselinglas.

Wenn man das allererste Mal ein Produkt von Lobmeyr in der Hand hält, spührt man dessen hohe Qualität und Feinheit. Lobmeyr ist einer der wenigen Hersteller, der die Glasbläserkunst par excellence beherrscht.

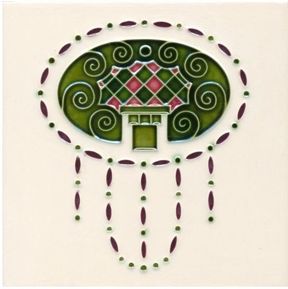

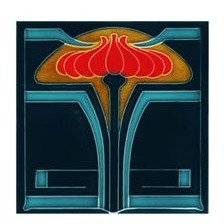

golem fliesen

Es bedarf der Idee, großer Leidenschaft und persönlicher Kompetenz um ein Porzellan aus der schon lange nicht mehr existierenden Porzellanmanufaktur Burgau als Replik wieder zu beleben und in limitierter Auflage herzustellen. Die Designerin Christina Klauer nahme das 1914 von Henry van der Velde entworfene Gedeck auf, das heute bei Reichenbach hergestellt wird.

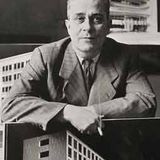

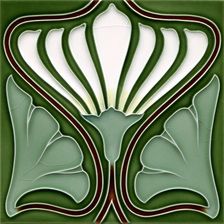

backhausen

Als einer der Hauptproduzenten der Wiener Werkstätten ist Backhausen Schnittstelle vieler Pioniere der Moderne. Seit Anbeginn bis heute pflegt das Unternehmen eine enge Zusammenarbeit mit Künstlern und auch jungen Designern. Die epochalen Werke von Josef Hoffmann, Koloman Moser und anderen dienen bis heute als wertvolle Inspirationsquelle für das Kreativteam des Designateliers.

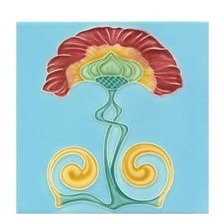

melone

1929 entwarf Josef Hoffmann, dieses weltberühmte Moccaservice. Er war einer der größten Gestalter des 20. Jahrhunderts und Mitglied der „Wiener Sezession“. Es stellt aufgrund seiner Rundungen höchste Anforderungen in der Handhabung des Luftpinsels an die Porzellanmaler von Augarten. Die Exotik der Fruchtformen mit dem kecken Stielknauf sowie die angenehm griffigen Henkel, deren leise Wellenform die weich gerippte Wandung der Gefäße elegant spiegeln, prägen die Ausstrahlung dieses Services.